Behind the Scenes at Starbucks Supply Chain Operations

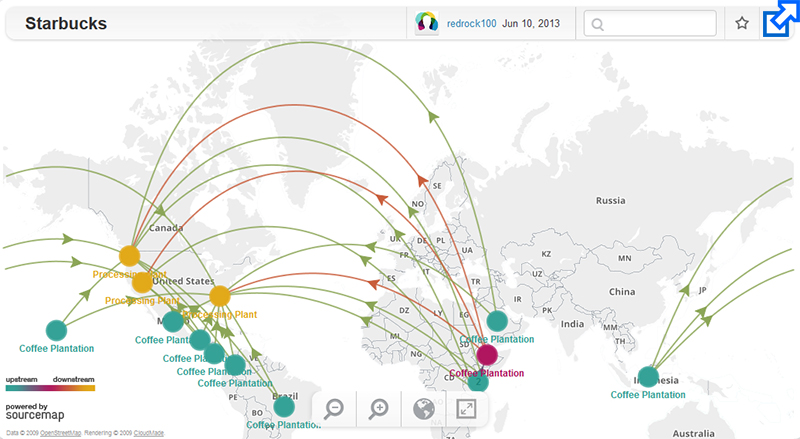

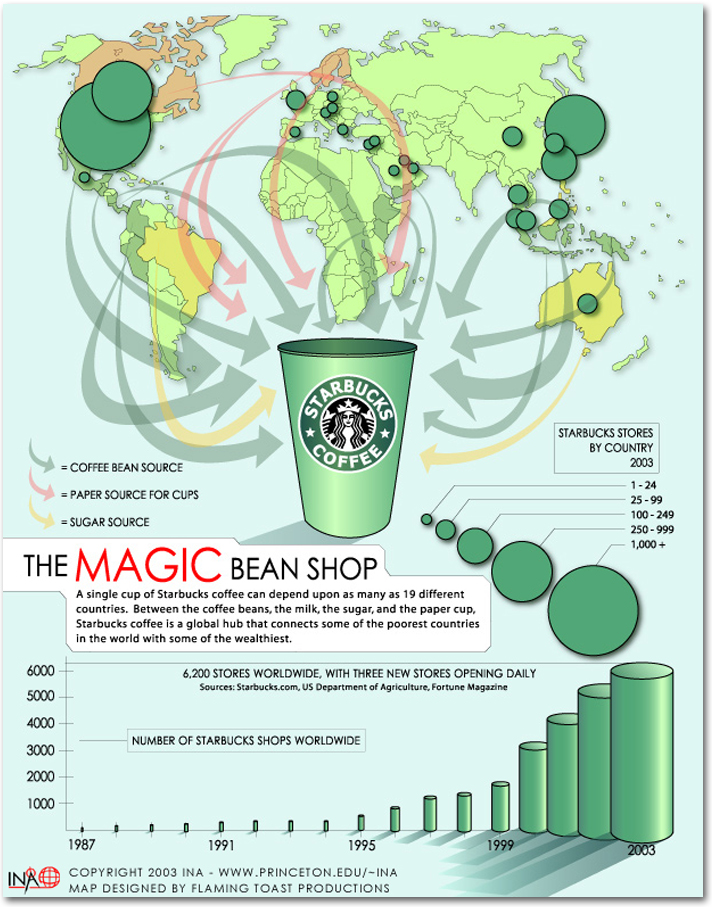

Starbucks has acquired an amazing supply chain that spans across almost nineteen countries.

Coco beans can come from one country while milk could come from an entirely different country hundreds of miles away!

This global resource span is a great way for Starbucks to expand the company and reach more countries than ever before.

Not only that, but Starbucks Coffee is able to supply the best ingredients to their customers for a lower price.

All raw materials are then sent to a roasting, manufacturing, and packaging plant.

Starbucks has six roasting centers where the beans are prepared. This number may seem very small for such an incredibly large company like Starbucks, but this centralized system is very effective.

These roasting centers make sure every single one of the beans is prepared, manufactured, and packaged in the exact same way and quickly through a series of well-designed manufacturing processes.

Once the beans are prepared, Starbucks has a tedious, well thought out delivery process.

The amount of coffee being deliver each day is astonishing (hundreds of thousands of pounds), but with over seventy thousand deliveries daily, Starbucks is able to supply each store with adequate amounts of coffee!

Originally published by Operations Management: Everyday Challenges and Opportunities.

Behind the Scenes at Starbucks Supply Chain (2 mins)